Manufacturing

Functionalities

Diglas Manufacturing enables the systematic management of production processes and is based on the principles of the MRP II (Manufacturing Resource Planning) methodology for resource planning. It is intended for manufacturing enterprises regardless of their size and complexity.

Key Functionalities:

- Defining multilevel material and labour standards:

- Components – material standards (structure, balance, cumulative, installation, substitution)

- Technology – labour standards (structure according to selected component, balance)

- Preparing calculations by combining components, technologies, price of materials and labor with or without adding elements that are not within the component and technology

- Analyzing and defining manufacturing needs on the basis of sale plans, buyers’ orders, manufacturing orders, internal requests or spare part plans

- Preparing and monitoring the realization of work orders (needs, review of work orders with analyses, review of component and labor consumption with analyses)

- Recording labor in manufacturing for individual employees or through group actions of authorized persons

- Web work records with the simple use of bar codes without use of keyboard and mouse

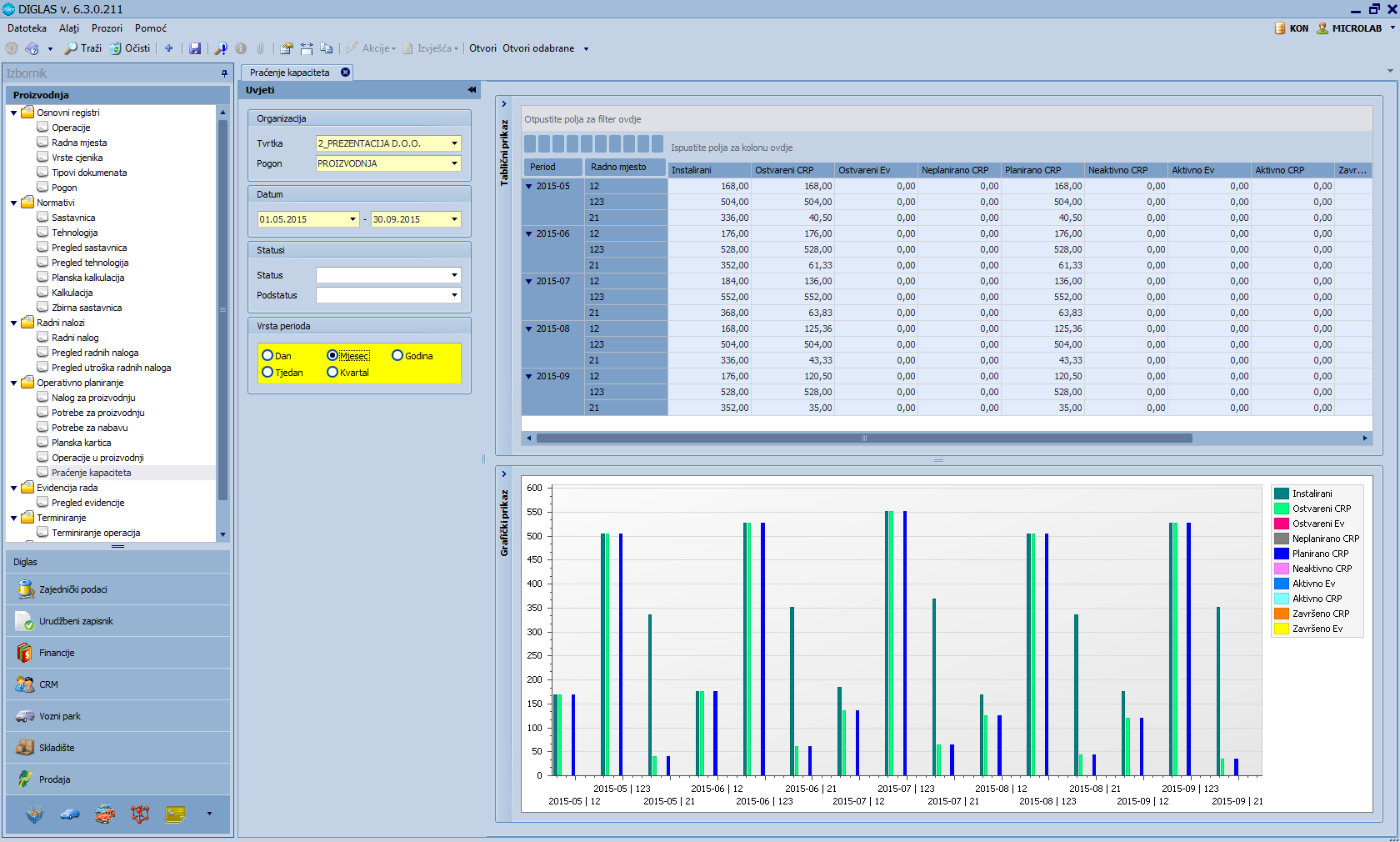

- Monitoring capacities by date, status, work place, day, week, month, quarter or year depending on the needs of the user

- Scheduling of operations according to work places

- Possibility of preparing integral interfaces with applications that manage the work of machines in manufacturing according to user requests

Quality Control

Functionalities

Diglas Quality Control enables the systematic management of product quality control activities.

Key Functionalities:

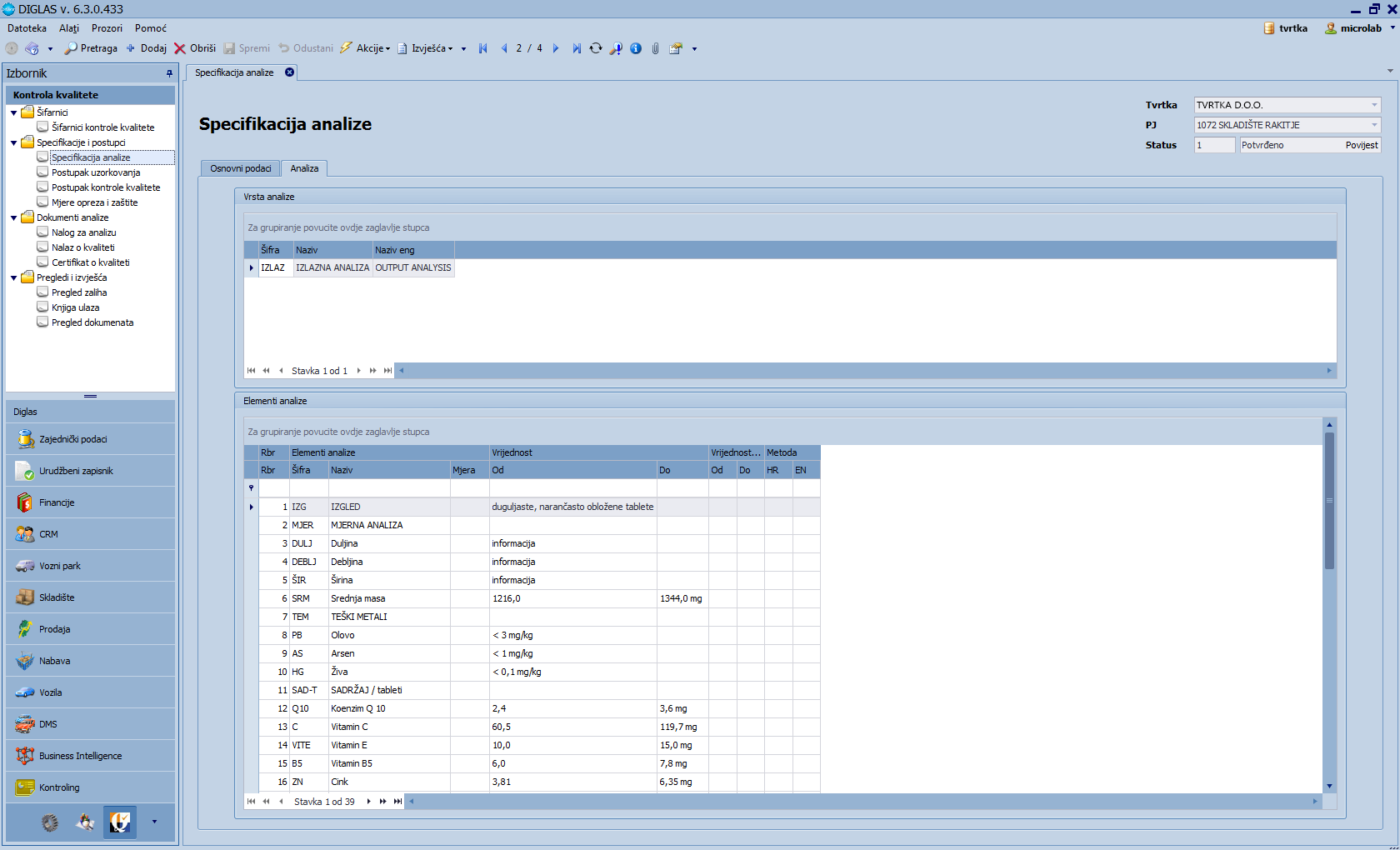

- Defining types and elements of analyses

- Defining quality status

- Configuration of the number of series

- Defining analysis specifications, sampling procedures and control at the product level

- Recording and processing analysis orders

- Recording and processing quality results which predefine behavior in the process

- Recording and processing of certificates accompanying specific products

- Monitoring the status of stocks and time limits and initiating the product re-analysis process

- Overview of data on the suppliers and product life cycles

- Overview of documents on implemented analyses

English

English Hrvatski

Hrvatski